Thermal Expansion

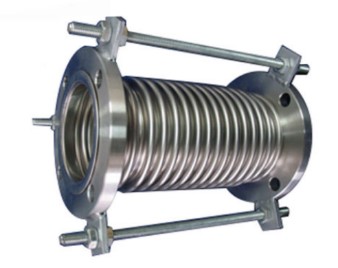

All raw materials have a linear thermal expansion coefficient. In construction for example windows and bridges are deliberately built using thermal gaps filled with expandable rubber or foam to compensate for expansion and contraction caused daily and seasonally by ambient temperature differences.

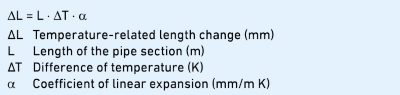

Piping systems are no different, whether metal, composite pipes or thermo-plastic pipes, straight lengths of pipe will contract or expand as ambient temperatures vary. Calculation of the linear movement can be done accurately by following the simple formulas as outlined in GF documentation below or by using the relevant digital tools. GF has been manufacturing and selling plastic pipe systems for >50 years : the practical experience gained over these years how to best compensate for this movement is explained below and in attachments. Please feel free to ask your local GF expert if you have any questions or require specific project support.

Training Courses from GF Piping Systems

Training courses for GF customers are available on request for the planning and design of plastic pipe systems. These courses are usually also CDP (Career Development Plan) supported and can offer practical as well as theory modules. Please enquire with your local GF expert for details.