NDT of GF Plastic Pipe Systems

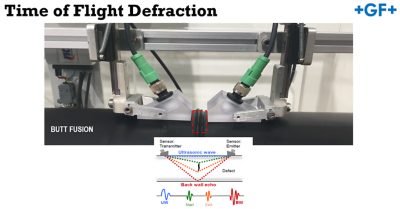

Using ultrasonic technology, GF is able to offer the highest quality control NDT for our butt fusion welds in ecoFIT, PROGEF and electrofusion jointing using ELGEF fittings. Key projects around the world rely on NDT technology to ensure highest safety and quality of the weld area in metal piping.

Today, GF Piping Systems' approach to total quality management has resulted in the world’s first NDT Service with a "pass" or "fail" statement on butt fusion and electrofusion welds using GF ecoFIT, PROGEF and ELGEF systems. Once passed we offer a weld warranty, contact your GF data center expert for details.

- 100% Objective Mathematical neutral logarithm

- Increase quality "Pass" / "Fail" weld report

- Increase safety Expert assurance from 60+ years of thermoplastics experience

- Save money 20-30 weld tests per day, increase efficiency, reduce on-site costs

- Save time Increase of life expectancy of ecoFIT / PROGEF piping system

Our NDT solution is a fast and flexible solution to test the quality of the installation on-site. Our experts can evaluate the condition of up to 30 welds per day with a single scanner. When the results confirm that the pipes are jointed correctly their performance is assured for the entire service life of the installation.