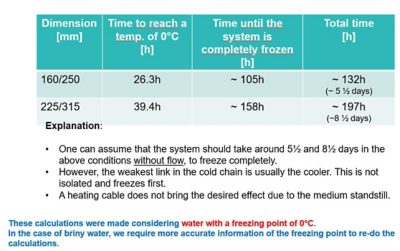

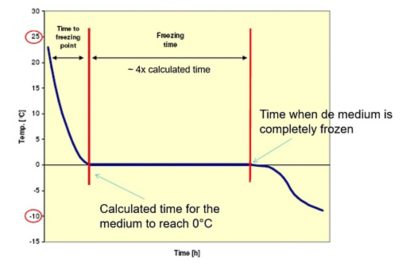

Time to freeze

When a pipe system containing a fluid is open to temperatures below the freezing point of the fluid there is a danger of the fluid freezing and hence potentially causing physical damage to the pipe

The GF COOLING Tool-Box offers an option to calculate the time which will be required for the fluid to completely freeze.

For larger dimensions the tie to freeze can often be >100 hours, however care should be taken that smaller dimension freeze quicker. Please refer to GF COOLING Tool-Box for COOL-FIT 2.0 and 4.0.

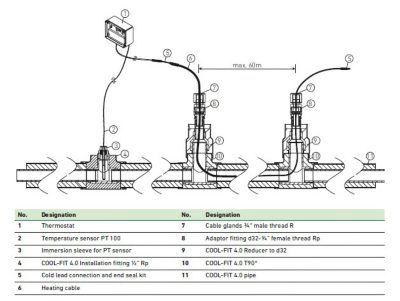

See downloads for technical installation details.