Plastic pipes weigh less

Plastic pipes weigh significantly less than metallic pipe systems. The plastic raw material has a density of about 0.9 to 1.5 g/cm3, compared to metal with a density of about 7.8 g/cm3 to 8.9 g/cm3.

The wall thicknesses of plastic to metal pipes varies but in general plastic pipe wall thicknesses are larger than metals. The density difference and also wall thickness differences leads to in general a piece of plastic pipe weighting approximately 5 to 7 times less than metal.

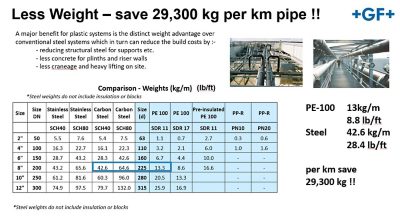

The table below shows the differences in plastic pipe weights to various selected metals. Especially for larger dimensions, ie > DN100 / 4" the resulting weight savings can be significant.

As well as the financial benefits such savings incurr, handling on-site and hence time on site is reduced thanks to the easy speedy handling of the plastic piping. For roof-top installations, where the mechanical contractors install tema asre open to the elements, see picture below as example, this time saving on-site is clearly beneficial to holding the ever more demanding tme to market demands of the end-suers.

The benefits of less weight for the piping are:

- The benefits this weight advantage brings are numerous but also sometimes difficult to evaluate financially.

- less structural steel work required

- building static load reduction

- reduced concrete requirements due to less structural weight

- crane weight carrying requirements reduced

- speed of handling and general transport increased

- health and safety: less weight to be handled reduces danger of accidents

A disadvantage of this weight reduction for plastics is the fact that the plastic pipe also has a higher E-Modulus, respectively a lower stiffness. This result sin pipe suoort distances less than metals. However the actual pipe support structure, and hence cost, is far simpler and cheaper, thanks to the lower weight to be supported. Hence at the end this disadvantage is small in comparison with the large advantage of reducing the toal overall weight of the piping.