Flexibility is essential in earthquake zones

GF ecoFIT PE-100 survives where metals cannot. PE-100 pipes are often used for gas and water distribution pipelines, these pipe networks are often underground and hence must be designed to bear the load of many external and internal stresses. These can be caused by ground movement, including earthquakes, as well as internal working pressure and general temperature fluctuations.

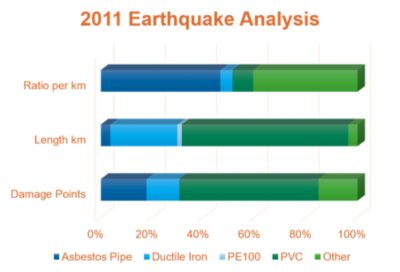

The reason why PE-100 is so resilient to seismic loads is its low modulus of elasticity. Thanks to its low modulus of elasticity the PE100 material is far superior in compensating the extranal loads caused by earthquakes compared to traditional metal pipes and other rigid piping systems. A

low E-Modulus allows the material to compensate itself under cycling loads, hydraulic shocks and external stresses.

Modulus of Elasticity measures the materials ability to withstand deformation (stress ÷ strain)

GF ecoFIT PE100 = 0.8 GPa

Carbon Steel = 150-200 GPa

Data Centers are ofen constructed in geographical regions suspect potenitally to earthquakes. Hence they need to undergo a seismic load simulation during the design phase. The types and range of stresses caused by the simulated earthquake depends on its geographical location. This can be simulated in the ROHR2 software stress analysis package available from GF Piping Systems.