Oxygen diffusion

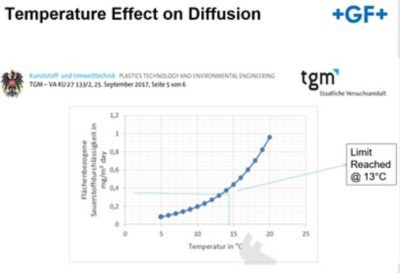

Oxygen diffusion through the wall of a pipe, from the environment into the transported fluid, can take place over a period of time, when the pipe material has a lower density, i.e. thermoplastic pipe systems.

It should be noted that oxygen diffusion will also take place via mechanical joints and suction sides of pumps however the following information only deals with oxygen diffusion through the wall of a thermoplastic pipe.

The amount of oxygen diffusion through the pipe wall is dependent on:

Time, pipe material, pressure, temperatures, wall thickness of pipe, surface finish of pipe internally and externally and density of pipe raw material.

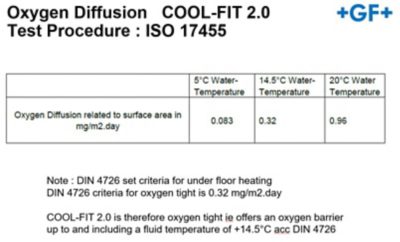

Oxygen diffusion through the wall of a pipe can be evaluated using a test procedure outlined in ISO17455, which was developed for heating systems. The reason for the ISO/DIN authorities development of this test procedure was that in 1970’s, with the introduction of plastic pipes for under floor heating, there was an increase in the amount of air respectively oxygen in the pipe systems. Modern under-floor heating systems use multi-layer pipes (Pex-Aluminium-Pex) where the aluminium layer offers an oxygen barrier, in terms of the pipe wall.

Use of plastic pipe can increase the corrosion effect on metallic parts in the pipe system for 2 reasons:

volume of O2 increases

- concentration of O2 attacking the metallic parts increases

For cooling systems there is currently no technical standard available or in progress, which defines limiting values for oxygen concentration in the cooling water.