Pre-Manufactured Value

What value does off-site fabrication offer ?

Off-site manufacturing ensures just in time logistics whilst producing operational assets that are leaner, greener and more efficient.

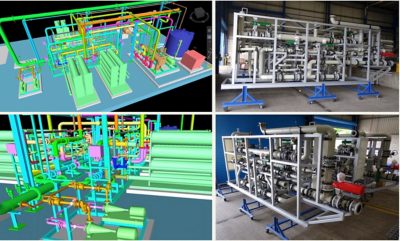

Off-Site fabrication offers significant efficiency gains, especially with regard to project planning and quality of workmanship. Plastic pipe systems, thanks mainly to their low weight, lend themselves perfectly to off-site fabrication. The handling of pre-fabricated spools or assembled pipe modules on the job site is far simpler with plastic pipes than would be possible with traditional metallic piping.

It is preferable to assess use of pre-fabrication early in the project lifespan, preferably in the design phase. GFs in-house engineering service can help give advice to the design and layout of the piping using plastics, for example offering support regarding expansion/contraction, stress analysis and pipe support distances and types.

At this stage of the project GF can recommend how to split the piping into manageable spools or running several systems parallel to enable design of pipe modules. You can benefit from 60 years of practical knowledge in designing, manufacturing and commissioning plastic systems, augment your own team with GFs specialists.

Consult your local data center expert for specific advice how GF can support your project with engineering support and pre-fabricated spools and modules.

Please accept all cookies to view the youtube video content.

What value does off-site fabrication offer ?

Off-site manufacturing ensures just in time logistics whilst producing operational assets that are leaner, greener and more efficient.

Off-site fabrication of complete plant rooms , even in large dimensions, will improve quality and ensure accurate project planning